Introduction to Brushless DC vs Brushed Motor

When it comes to electric motors, two of the most common types are brushed motors and brushless DC motors. The debate between brushless DC vs brushed motor revolves around efficiency, performance, lifespan, and maintenance. Choosing the right motor depends on the specific application, desired performance, and long-term reliability. Understanding the fundamental differences between these two types can help engineers, hobbyists, and manufacturers make informed decisions.

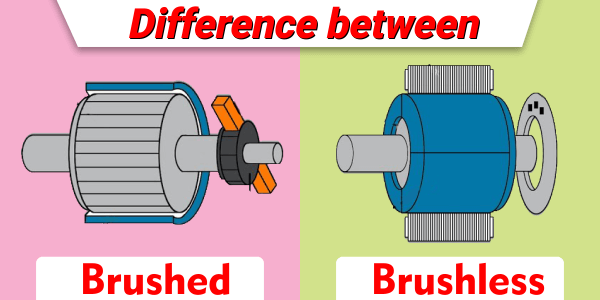

Design and Construction Differences

A brushed motor is built with a simple design consisting of a rotor, stator, brushes, and a commutator. The brushes are in constant contact with the rotating commutator, which allows electrical current to flow through the windings and generate motion. This mechanical contact is the main characteristic of brushed motors and is both a strength and a weakness. On the other hand, brushless DC motors eliminate brushes entirely and rely on electronic controllers to switch the current in the motor windings. The rotor is usually a permanent magnet, while the stator contains the electromagnets. This fundamental difference in design is one of the main reasons why brushless motors tend to outperform brushed motors in several aspects.

Efficiency and Performance

Efficiency is a critical factor when comparing brushless DC vs brushed motor. Brushed motors are generally less efficient due to friction caused by the brushes and the commutator. This friction results in energy loss in the form of heat, which can affect performance, especially under heavy load or prolonged operation. In contrast, brushless DC motors are more efficient because they do not have brushes. The electronic commutation ensures that power is delivered more precisely to the motor windings, reducing energy loss and heat generation. This increased efficiency translates into better performance, higher speed capabilities, and longer operational periods without overheating.

Maintenance Requirements

One of the most significant differences between brushless DC vs brushed motor is maintenance. Brushed motors require periodic maintenance because the brushes wear down over time and need replacement. The commutator can also degrade, requiring inspection and servicing. Brushless DC motors, however, have minimal maintenance needs. Since they lack brushes, there is no frictional wear, and the motor can run for thousands of hours without intervention. This makes brushless motors ideal for applications where long-term reliability is crucial or where maintenance is difficult.

Lifespan and Durability

Lifespan is directly affected by the wear and tear on a motor’s components. Brushed motors typically have a shorter lifespan due to the mechanical contact between brushes and the commutator. Excessive heat and friction accelerate wear, which can lead to premature failure. Brushless DC motors, on the other hand, have a longer lifespan because they eliminate this point of mechanical stress. The absence of brushes reduces friction, heat generation, and the likelihood of component failure. As a result, brushless motors are often the preferred choice in demanding applications that require consistent, long-term performance.

Applications and Use Cases

The choice between brushless DC vs brushed motor often comes down to the intended application. Brushed motors are still widely used in simple devices where cost and simplicity are more important than efficiency or lifespan. Examples include household appliances, toys, and small power tools. Brushless DC motors are favored in applications that demand high efficiency, reliability, and precise control, such as drones, electric vehicles, robotics, and high-performance industrial equipment. The ability of brushless motors to operate efficiently under continuous load makes them ideal for modern technology that relies on longevity and minimal maintenance.

Cost Considerations

Cost is another factor when comparing brushless DC vs brushed motor. Brushed motors are generally less expensive due to their simpler design and lower manufacturing complexity. Brushless motors, however, require additional electronic controllers, which increase the initial cost. Despite the higher upfront price, the long-term benefits of higher efficiency, lower maintenance, and extended lifespan often justify the investment in brushless technology.

Conclusion

Understanding the differences between brushless DC vs brushed motor is essential for anyone looking to select the right motor for their project. While brushed motors offer simplicity and low initial cost, they fall short in efficiency, maintenance, and durability. Brushless DC motors provide higher efficiency, longer lifespan, and reduced maintenance, making them suitable for applications requiring performance and reliability. Ultimately, the decision between these two motor types depends on balancing cost, maintenance needs, and operational requirements.

Follow Us On Tiktok For More Information:

https://www.tiktok.com/@origin_data